COFFEE ROASTING

Transforming green beans into the aromatic coffee we love depends on one vital piece of equipment – the coffee roaster. But how much do you know about the history of the coffee roaster? Why is it designed in the way it is, and how has it changed throughout history?

ROASTING COFFEE IN PANS

Coffee has a long, rich history. Preparing roasted coffee beans to make a drink is thought to date back centuries to Africa and the Middle East. The Ottoman Empire and European colonization then took the drink around the world.

The first known roasting tools were thin, perforated pans that were used over an open flame. The roaster would use spoons to move the beans around and ensure even roasting.

Only a small amount of beans could be roasted at a time, and the stirring meant that the roaster had to pay close attention throughout the whole process.

THE CYLINDRICAL COFFEE ROASTER

It’s reported that cylindrical roasters originated in Grand Cairo in the 17th century. These devices enclosed the beans, allowing heat to develop inside the chamber. They also featured hand cranks to move the beans around consistently while the device was held over an open flame.

This design also meant reduced fumes, which made roasting coffee more comfortable. Cylindrical roasters were tweaked and adapted through the years, but the central concept remained the same. The design spread throughout Europe and the Americas as colonialism grew the coffee industry.

THE INDUSTRIAL COFFEE ROASTER

Coffee roasting was no exception to industrialization. In the 19th century, various patents were awarded in the US and Europe for commercial roasters, although many people continued to roast their own small batches at home.

Many early industrial roasters were simply large cylinders placed over a heat source. Until the introduction of gas supplies throughout urban centers, wood or coal was used. But this gave the coffee a smoky flavor, so when natural gas became available, it soon became the roaster’s preferred heat source.

THE IMPACT OF ELECTRICITY

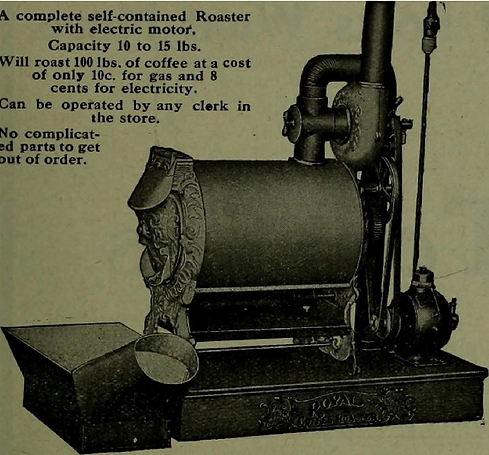

As electricity grew more accessible at the turn of the 20th century, the coffee roasting industry adapted.

Electric motors meant that roasting became much less labor-intensive. And because electric heat is more predictable than open flames, the roast was more consistent, as well as less dangerous. For the first time, roasters were able to control exposure to heat with some accuracy and had better ability to replicate conditions.

FLUID-BED ROASTERS

Drum roasters based on 19th century patents are still the roaster design of choice today. But in the 1970s, fluid-bed or hot-air roasters entered the scene.

In a fluid-bed roaster, heated air is forced through a screen under the coffee beans with enough strength to lift the beans. Heat is transferred to the beans as they tumble around. Michael Sivetz, an American chemical engineer, patented the design in 1976.

Roasters have largely dismissed fluid-bed roasters as not providing the same quality of roast, which is attributed to them using just convection, rather than the combination of convection, conduction, and radiation created in a drum roaster.

NEW TECHNOLOGY

Modern coffee roasting is informed by better understanding of coffee chemistry and what changes happen during the process. Roasters are better equipped to measure variables and analyze why a roast is successful or not. With technologies such as digital temperature reading and profiling software they can be more efficient and consistent than ever before.

But these innovations are dependent on core inventions from over a century ago. Contemporary additions can help us better control the roast, but they are essentially fine tuning of the 19th century drum roaster.